|

Although the two SuperRelm lathes look similar no two bits

are quite the same and indeed are not interchangable. At first I thought

this was early-20th century British

hand-crafted engineering, but having researched the company I now believe

this is the result of trying to reduce costs and improve the product.

My primary lathe,

with its brass serial number plate 'Cheltenham Works, Makers, No 1233', I think

is the earlier of the two, dating from around 1916, and the finish of the casting is much better.

I believe the SuperRelm 100 had subtle changes to make it cheaper and easier to manufacture and is the later

machine, showing a higher degree of mechanisation in its construction.

One most obvious change is that the brass name plate has gone (not just missing as there are no holes to mount it)

and the word SuperRelm is cast into the bed.

There are examples with both so this may well have been transitional, probably as stocks of the old patterns were used up, but it might also reflect

the fact that both the Relmac and SuperRelm were offered for home/vendor assembly and therefore the nameplate

might only be fitted to those that were factory assembled.

On the later SuperRelm 100 there is a square edge to the top rear of the

headstock bearing blocks while earlier ones are similar to the early Relmac with a

rounded edge. Again this appears to be transitional. Early Relmacs had the

bearing clamp screws at the back and a handle on the leadscrew rather than a handwheel.

On later models the clamp screws were moved to the front and the name Relmac was cast in the

bed suggesting some convergence in patterns, making the headstocks identical. It is likely that the SuperRelm 100 came into being either in late 1916 marking the change of name of the company or around 1919, possibly marking 10 years of the company. In either case it is probable that at this time the Relmac gained the same headstock arrangement

Other subtle differences between the two SuperRelms, that have been seen on other examples, are:

The brass plate with the thread-cutting info is smaller on the later lathe

The feet are not as deep, the earlier SuperRelm being identical to the Relmac and a good inch taller.

On the cross slide and topslide screws the support

bearings are smaller and identical (on the earlier lathe they are clearly hand-finished and unique)

The cross-slide and top-slide nuts on the earlier lathe are different and show

signs of hand finishing on the mounting lug and on the rounding of the edges, whereas the later

lathe has identically machined nuts.

the apron casting on the later lathe is thinner and the cavity for the half-nuts is machined square

allowing the halfnuts to be identical and inserted/removed without removing the leadscrew. On the earlier

lathe the upper halfnut top face is rounded to match the more roughly machined internal radius of the casting

and cannot be removed without removing the leadscrew.

the later halfnuts are slightly longer

the castings for the cross and topslide are slightly wider on the later lathe

the topslide gib has moved to the front; and

the lockdown for the tooling (which might not be original anyway).

Examples of other SuperRelm and Relmac lathes I have found on the web can be seen

here.

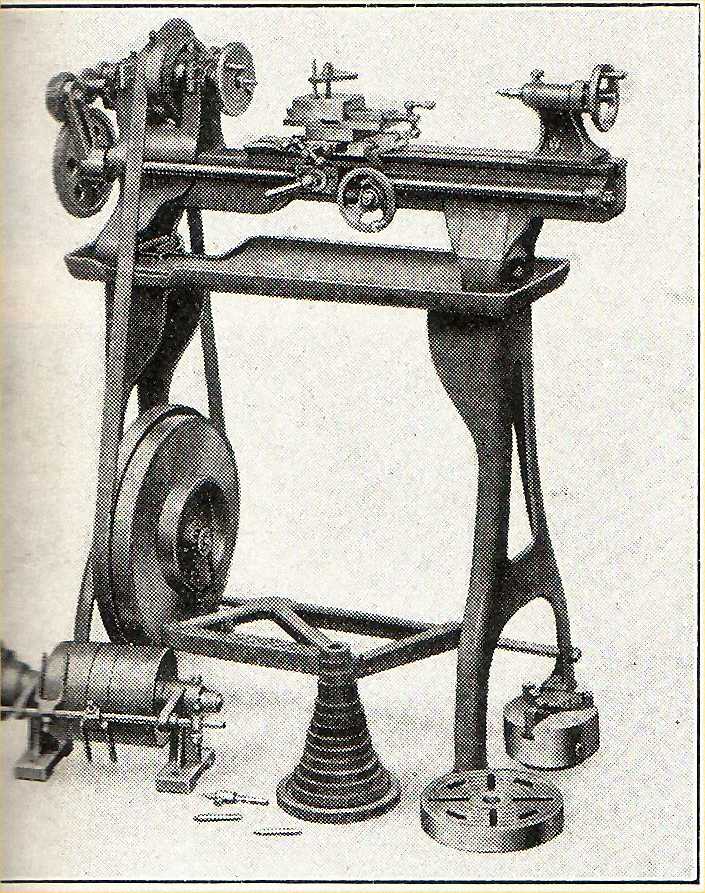

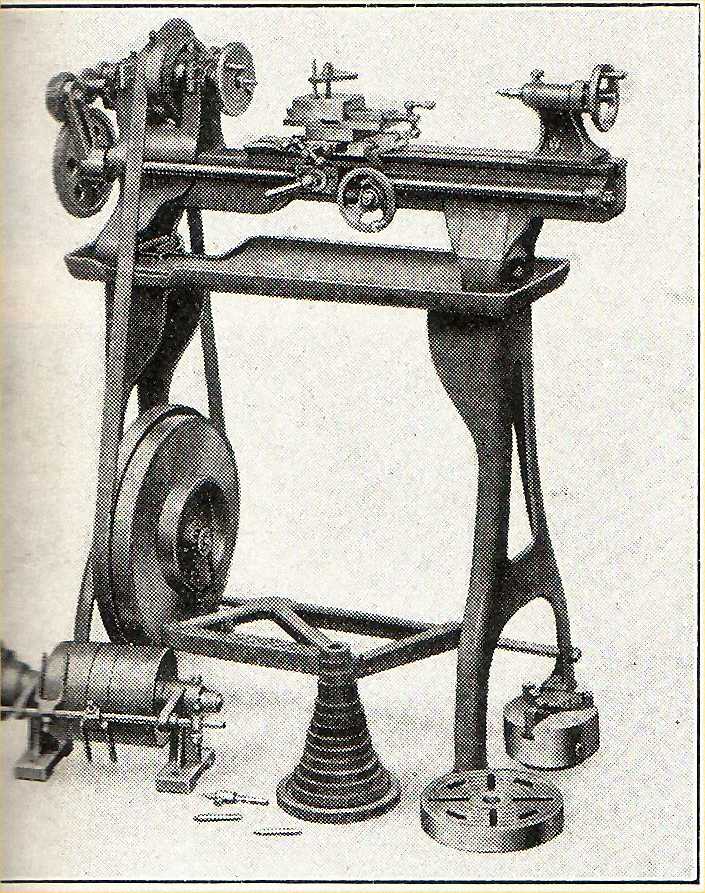

Another picture of an early SuperRelm from the 1922 Model Engineer magazine. Although

an artists impression, note the lack of the SuperRelm name in the casting

Another picture of an early SuperRelm from the 1922 Model Engineer magazine. Although

an artists impression, note the lack of the SuperRelm name in the casting

|

Another picture of an early SuperRelm from the 1922 Model Engineer magazine. Although

an artists impression, note the lack of the SuperRelm name in the casting

Another picture of an early SuperRelm from the 1922 Model Engineer magazine. Although

an artists impression, note the lack of the SuperRelm name in the casting